GEMAC Motus®

New possibilities for the individualization of inertial measurement units

New possibilities for the individualization of inertial measurement units

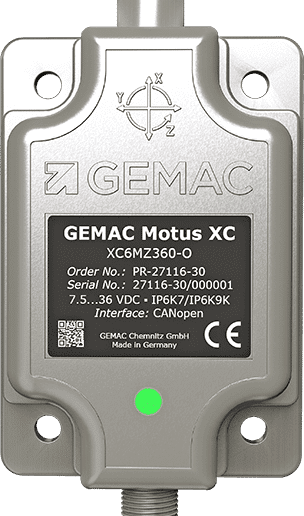

With the market launch of the GEMAC Motus in 2020, a sensor measuring unit configurable for a wide range of applications was introduced, which enables 6-axis motion detection on mobile machines, such as construction machinery, agricultural machinery, forestry machinery, crane and lifting technology, as well as on ships.

The market has very well received our FIRST POWER-IMU for high-precision measurement on mobile POWER machines. Various suggestions from our customers for further completion of the scope of performance have been implemented in new functional extensions. These focus in particular on the possibilities for individualization in specific customer applications:

1. Automatic configuration of the mounting position

For the first time, GEMAC offers the option of individually configuring the mounting position and axes for the tilt output for the entire GEMAC Motus family, adjustable by manual parameters or direct automatic position adjustment. This makes it even easier and more flexible to adapt the sensor to the application.

2. Flexible zero adjustment

The previous offset only affected the plumb angle output. The offset values were previously added up at the end of the inclination calculation. The improved offset setting now makes it possible to rotate the sensor’s coördinate system. More flexible measuring ranges can be realized, and every angle format can be calculated even more precisely.

3. Configuration of sensor fusion

Furthermore, the software implemented an expert mode with extended setting options, which allows a configuration of the sensor fusion. Here, the new option of deactivating the filter dynamics (adaptive damping) and the manual setting of the damping factor enables even more stable output values for very dynamic applications or permanent movement of a mobile machine.

4. Configuration of the output data at SAE J1939

Until now, SAE J1939 offered only four standardized output telegrams and several proprietary telegrams with other output data. Like CANopen, each signal is assigned its ID, which can be mapped into an output telegram. Up to 4 signals per telegram are possible. The output data can thus not only be configured and evaluated manually but also individually.

5. CANopen Autostart

With this new option, it is possible that the sensor goes directly into the CANopen mode “Operational” after the “Power-On” or “Reset” without having to receive a start telegram from the CANopen master. This makes it possible to configure the sensor so that directly measured values can be output with the “Power-On” without additional communication.